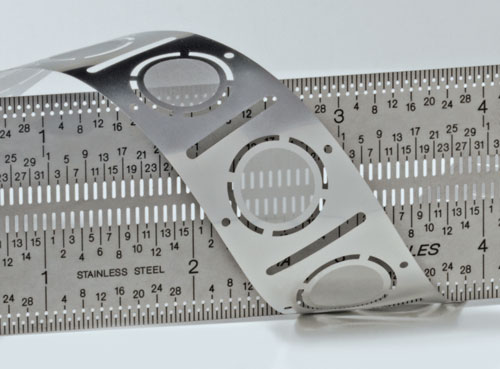

Sometimes an application requires ultra-fine micro features and tolerances that cannot be achieved with even the best controlled metal stamping process. That is where chemical etching comes into play, with the ability to create highly-repeatable, burr-free components with complex features as small as 1.2x of the material thickness.

Using a tightly-controlled reel-to-reel process enables these micro-features and intricate metal designs or shapes to be produced on a continuous metal strip using a wide variety of ferrous and non-ferrous materials, thereby facilitating the use of reeled components within automated production environments.