Fluid filtration and control systems are becoming more complex and are a critical element for many of today's advanced automotive, aerospace, medical and consumer applications. The flow rates and pressure levels of a variety of different liquids are key factors for actuating or controlling processes within these systems, such as automotive valve actuation based on oil pressure levels. Fluid filtration is also an important process for removing fine particulates from systems to avoid damage to sensitive components such as pumps, valves and motors.

When the application requirements need both high strength and close tolerances, with a high level of part repeatability, the only real solution is to use a well-controlled reel-to-reel chemical etching process for creating the metal filtration parts.

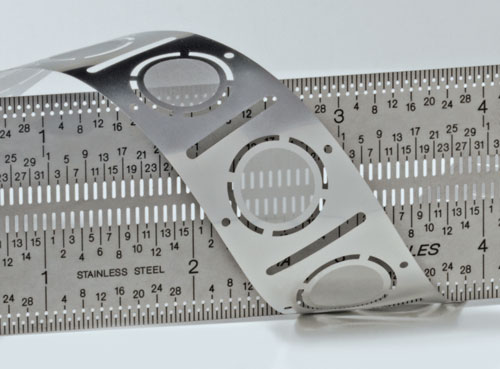

Chemically etched metal filter screens are fabricated out of sheet metal alloys producing a structurally strong design for screen applications. Etched metal screens are superior to steel wool and wire mesh because they are capable of filtering out much smaller particulates.

Etched screens will not fray, open or distort. In addition, the chemical etching process allows for a variety of mesh opening sizes as well as unique hole shapes, such as round, square and hexagonal holes. Hole patterns also can be tailored to meet the specific filtration requirement.

Using a tightly controlled reel-to-reel etching process is important to maintain the close tolerances and a high degree of repeatability combined with high-volume production output. Unlike panel etched parts, reel-to-reel etching is inherently automation friendly and allows for smooth integration of secondary processing steps. For example, the etched metal filtration parts can be easily formed, plated or insert molded using various types of automated equipment.

The reel-to-reel chemical etching approach offers excellent control and the flexibility to design parts that meet virtually any specific application requirements for Particulate Size, Liguid Flow and Pressure levels using a variety of Material Types and Thickness.

As the sophistication of systems increases, the need for reliable filtration protection becomes ever more critical. The filtering of smaller particulates requires smaller holes and high liquid flow rates require larger hole-count densities. To achieve both, chemical etching is on the only process to create these filters with consistency and high repeatability.

Click here to learn more about using chemical etching for making precision flltration parts.