Maintaining sufficient retention force is absolutely critical for the long-term operational integrity of any

press-fit interconnection. Therefore press-fit zone designs must be tested to meet the application's

minimum retention force requirements and operating environments using IEC-60352-5 requirements

as a baseline guide.

Testing both before and after multi-axis environmental stress includes but is not limited to: thermal shock, high/low temperature exposure, vibration, climatic cycling, temperature and humidity cycling and other similar test requirements. In addition, to assure a wide process control window for assembly and to minimize deformation to the plated-through hole, it is important that press-fit zone designs conform to maximum insertion force parameters.

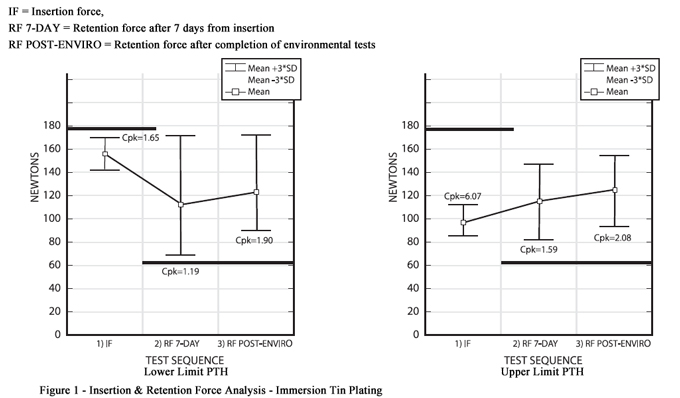

The analysis of insertion and retention forces should be performed for both minimum and maximum

plated-through-hole (PTH) size specifications. Retention force must be measured for both pre and

post environmental stress conditions.

For example, the whisker plots below, show insertion and retention forces for an Interplex 0.80mm press-fit interconnect in Newtons, for insertion (IF) and retention (RF) after 7 days and post-environmental testing. Testing is performed for both Upper Limit and Lower Limit PTH hole sizes.

Mechanical analysis of insertion and retention forces is one of the three key techniques used to

assure the integrity of solderless press-fit interconnects. For more information, read the detailed Tech Bulletin on Mechanical Force Analysis for Press-Fit.

Also, for information on the other two key test areas, read the Tech Bulletins on Cross Section

Analysis and Contact Resistance.