For over 50 years a variety of Press-Fit connectors have been widely used in the telecom and industrial markets. The technology available for those markets works well in most controlled environment applications where mobility, vibration and harsh environmental conditions are not encountered.

For over 50 years a variety of Press-Fit connectors have been widely used in the telecom and industrial markets. The technology available for those markets works well in most controlled environment applications where mobility, vibration and harsh environmental conditions are not encountered.

The ongoing development of electronic systems for use in such applications as automotive and transportation systems and green power applications requires the units to operate under quite aggressive conditions and severe ambient environments. Over recent years, there have been several significant design upgrades and changes to past press-fit designs that were needed to move the technology to support these harsher environments.

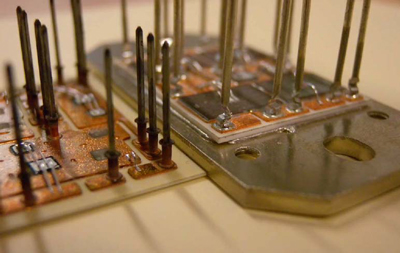

Press-fit technology has come a long way over recent years and has been adapted for use in a wide range of applications in diverse industry segments, including automotive, power modules, transportation, industrial equipment, communication systems, appliances, lighting, utilities, green energy, mobile devices, wearable electronics and many other consumer products.

Press-fit technology has come a long way over recent years and has been adapted for use in a wide range of applications in diverse industry segments, including automotive, power modules, transportation, industrial equipment, communication systems, appliances, lighting, utilities, green energy, mobile devices, wearable electronics and many other consumer products.