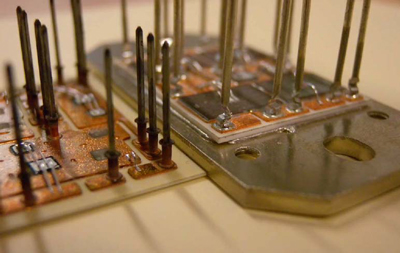

Maintaining sufficient retention force is absolutely critical for the long-term operational integrity of any

press-fit interconnection. Therefore press-fit zone designs must be tested to meet the application's

minimum retention force requirements and operating environments using IEC-60352-5 requirements

as a baseline guide.

Testing both before and after multi-axis environmental stress includes but is not limited to: thermal shock, high/low temperature exposure, vibration, climatic cycling, temperature and humidity cycling and other similar test requirements. In addition, to assure a wide process control window for assembly and to minimize deformation to the plated-through hole, it is important that press-fit zone designs conform to maximum insertion force parameters.

Press-fit technology has come a long way over recent years and has been adapted for use in a wide range of applications in diverse industry segments, including automotive, power modules, transportation, industrial equipment, communication systems, appliances, lighting, utilities, green energy, mobile devices, wearable electronics and many other consumer products.

Press-fit technology has come a long way over recent years and has been adapted for use in a wide range of applications in diverse industry segments, including automotive, power modules, transportation, industrial equipment, communication systems, appliances, lighting, utilities, green energy, mobile devices, wearable electronics and many other consumer products.