Posted by Power Products Design Team

Aug 27, 2015 10:14:00 AM

Topics: module design & manufacturing, automotive, power applications

Posted by Interplex Engineered Products team

Feb 5, 2015 10:05:00 AM

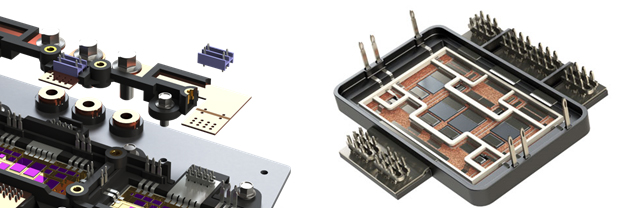

The Air Cavity Package (ACP) is a widely used option for RF products, hybrid circuit assemblies, as well as optical/photonic devices. Typical ACP’s have consisted of metal cans and ceramic leadless chip carriers (LCC). Custom ACP’s are also provided by machined metal housings and LTCC options.

However, over the past 10 - 15 years, the development of MEMS Sensors and LED devices has seen the use of thermoplastic pre-molded leadframe packages become the top choice for custom application specific housings. These products are now maturing and moving to “standard” package outlines where possible.

Liquid Crystal Polymers (LCP) are the choice for plastic body components and connectors, developed to suit temperatures of 300 degrees C and above. This means that packages made with such materials can withstand the typical reflow soldering processes used in high-volume system manufacturing.

Following are some key considerations for achieving success with LCP based packaging.

Topics: module design & manufacturing

Posted by Sensors Team

Apr 24, 2014 8:46:30 PM

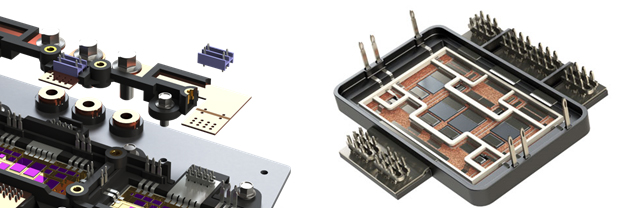

Electronic modules, sensors and MEMs applications are proliferating throughout a variety of industries and are driving a need for new and better methods for creating interconnections - both internally within the modules and also to provide external connections from the modules.

Many applications utilizing electronic systems need fully Integrated, modular, ‘plug & play’ package units with multiple internal connection platforms that support the combination of various technologies from chip-level up through mini-board and module level.

Even as feature-rich complexity of the module designs continues to increase, the associated interconnect complexity needs to be held to a minimum.

The optimal approach is to combine injection molding with fine precision stamping of metal interconnection platforms that are plated for a variety of application-specific wire bond requirements.

Topics: SENSOR+TEST, module design & manufacturing, sensors, MEMs

Posted by Press-Fit Team

Apr 14, 2014 8:41:00 AM

Let's face it. Some things just naturally belong together.

Press-Fit/Compliant technology and insert molded plastic electronic modules are definitely one of those perfect matches that makes a lot of sense from the start and then just keeps getting better with time.

Topics: module design & manufacturing, sensors, Press-Fit compliant interconnects, power modules, insert-molding

Compliant/Press-Fit technology has already been established as a proven standard in automotive electronics, power modules and other areas, which enables solder-free interconnects with high reliability and cost-saving process simplification. The ability to eliminate soldering hassles along with delivering excellent thermal characteristics and high-current carrying capacity has made press-fit a preferred solution in these arenas.

These advantages are now also driving the adoption of press-fit technology in a widening array of applications, including wearable tech products, medical monitoring devices, and industrial systems. In response, suppliers are expanding the configurations and size ranges of available press-fit interconnects to meet this expanding range of needs.

Today's press-fit offerings go well beyond the standard sizes, such as .64mm and .80mm, which have become ubiquitous in automotive and power applications. New Micro, Mini and Macro version are addressing the needs of markets like wearable electronics, medical monitoring devices and high-current industrial busbars.

Topics: module design & manufacturing, Press-Fit compliant interconnects, wearable electronics

This year's SENSOR+TEST exhibition will be held in Nürnberg, Germany from 3‐5 June 2014.

As always, we're looking forward to seeing the newest advances as well as showing the latest technologies from Interplex. The chance to interact and share ideas with other leaders in the sensor marketplace and to understand the real-world challenges facing hands-on engineers is invaluable to us.

Topics: SENSOR+TEST, module design & manufacturing, sensors

Interplex "Junction" is your place to learn the latest on applications-focused technologies, such as: